⚙Similar to all the equipment and products manufactured by Midwest Custom Solutions, our 36-8 Baghouse is engineered to withstand your demanding operational environments and assembled with only high-quality materials and fasteners to provide you with the most value for your investment dollars.

⚙Our 36-8 Baghouse features 36 CS Series Venturis coupled to Split-Collar filter cages and filter sleeves. All mounted below the Air Cap to ensure superior dust collection and filtration while providing ease of maintenance and inspection of critical components.

⚙Do you require specific venturis, filters/media or filter cages? We can provide precisely what you need to ensure your processing operations run at peak efficiencies while safeguarding and minimizing any environmental impacts you may encounter.

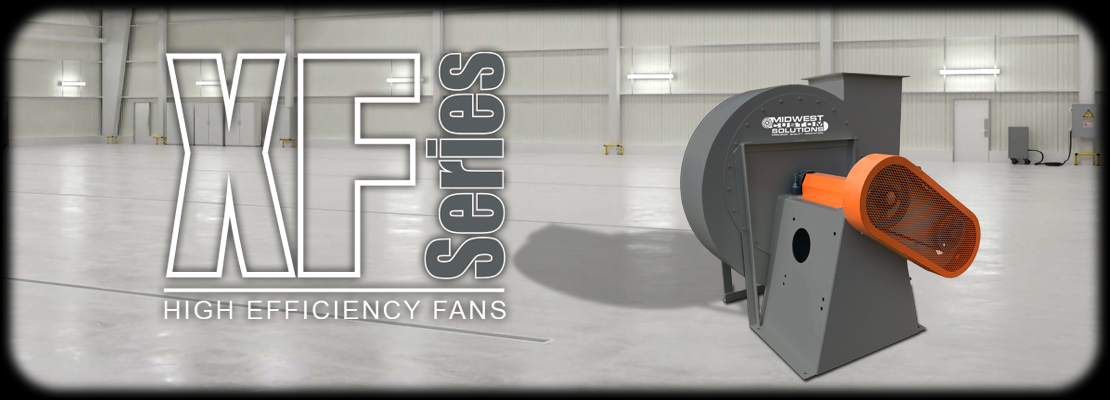

⚙Our 19in Fan comes standard with the 36-8 Baghouse and is built with industry-leading serviceable bearings for long-lasting, smooth performing operations. Likewise, the fan's drive motor is a top-quality selection to ensure you receive the highest performance, longest lasting piece of equipment for your investment dollars.

⚙We’ve strategically incorporated pick-points into our 36-8 design for easy, quick and worry free movement and lifting of the Baghouse - something few consider until several thousand pounds of steel are hanging in the air from the boom of a crane.

⚙Industry-leading Diaphragm Valves are offered as a standard feature on our 36-8 Baghouse, operating in conjunction with the integral timer box to ensure pulse-pressure cleaning of the system and filter media. At MCS, we know how much you depend on our equipment to function properly within your processing operations - ensuring the filter media remains effective and efficient in our baghouses is a primary concern.

⚙All structural framing members, door and mounting hardware is designed to withstand rigorous use and demanding air pressures to ensure safe operation while providing thorough particulate filtration to meet environmental requirements.