⚙At Midwest Custom Solutions, we know you expect to get the most from your equipment investment dollars. It's for this reason we refuse to compromise on material selections, manufacturing processes or finishing standards. We know how much you depend on your equipment - providing a long-lasting, worry-free product investment is our primary goal.

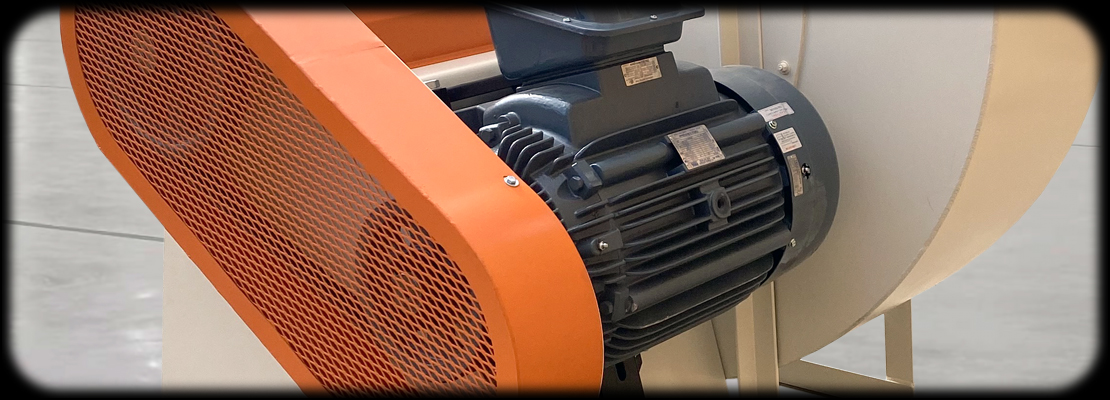

⚙That's why we install only industry-leading serviceable bearings on all of our fans for a smooth-running means of air movement and countless hours of worry-free run time.

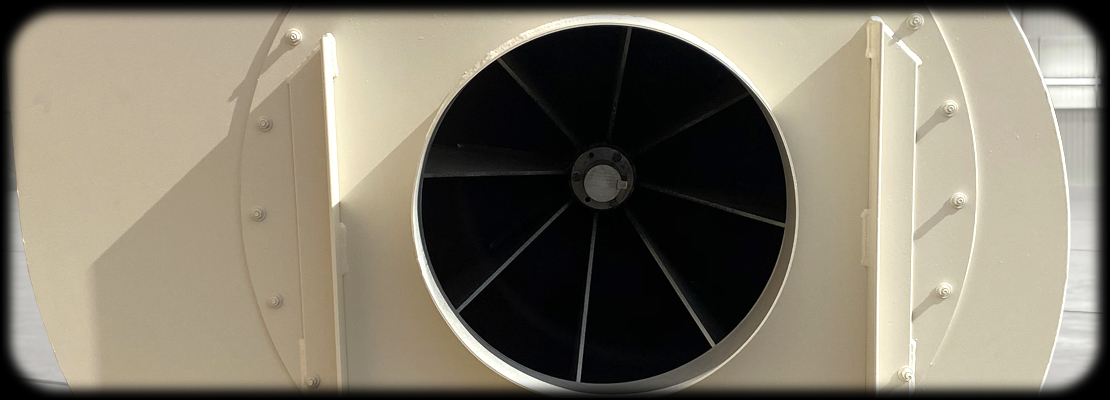

⚙Our XF Series fan rotors are constructed from Abrasion Resistant AR235 material standard, incorporating engineered designs and strict manufacturing practices to ensure this critical component is able to safely withstand the rigors of your most demanding operational environments. MCS is also able to provide rotors manufactured in T1A, AR235, AR400, AR500, 304SS, 316SS and Hardox or as specified by the client.

⚙We also ensure that each and every one of our fan rotors is precision balanced for vibration-free, quiet performance and years of service in your most demanding operational environments. Vibration-free operation also means less operational stress placed on support structures and adjacent equipment.

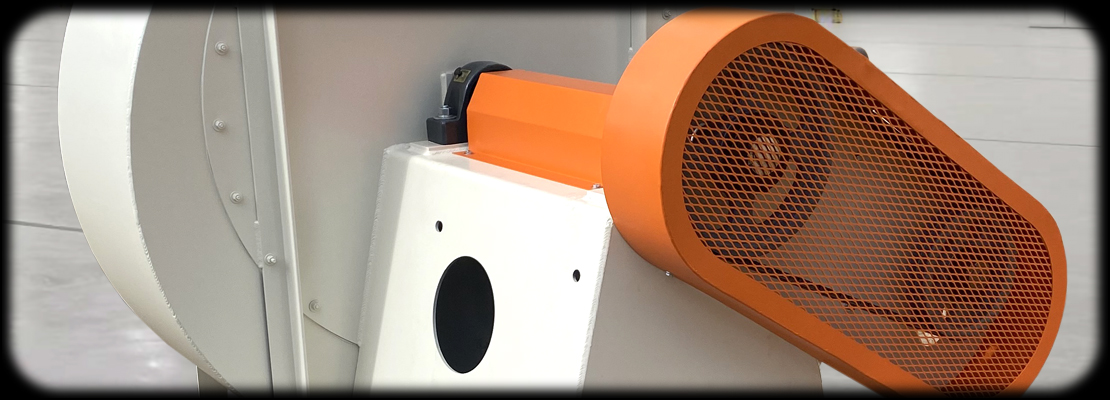

⚙Each of our fans if offered with optional fan rotation direction and discharge orientation. We know that not all equipment performance requirements will be the same, so be sure to speak with our sales team to ensure we make your installation care-free.

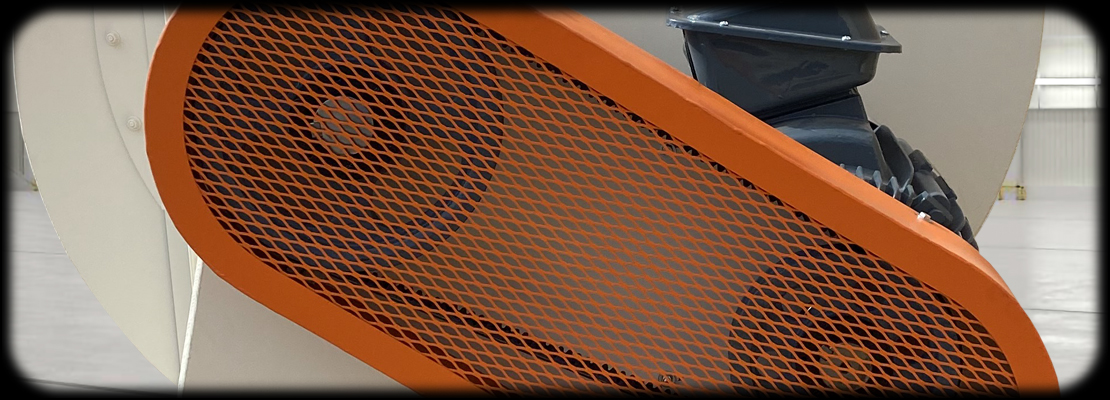

⚙Rotor shafts are precision-machined to exacting specs with durability and safety as prime considerations. Rugged and stout belt shrouds are also engineered to provide maximum operational safety for those who work within the equipment's proximity.

⚙All MCS fans are built from quality materials and assembled by skilled technicians. Frames and rotors are offered with mild steel construction standard, however, we also provide for a materials selection with specific fan applications or installations in mind.